Choose and Free Access

- Bending

- Presses

- Pipe/Profile bending

- Production Line

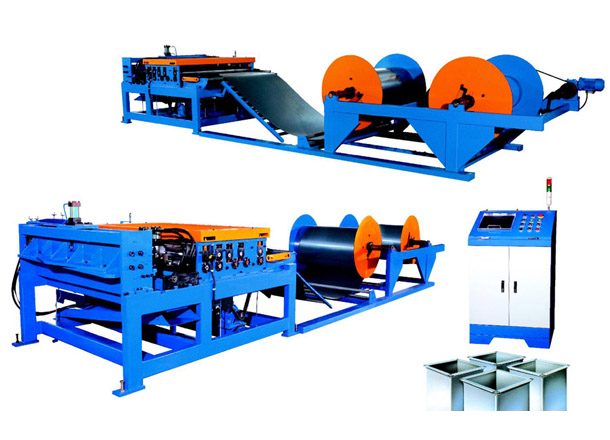

DUCT MANUFACTURE LINE-2

- Details

Products Information

Auto-line II consists of a metal feeding frame, levelling and grooving equipment, notching and punching square equipment, cutting equipment. The electrical control system uses a computer which combines with a closed-loop servo-system to increase the precision and stabilization of the line. The maximum working speed is 10m/min. The length tolerance is ±0.5mm. The diagonal line tolerance is ±0.8mm . The feeding frame can be set as the customer’s requirement.

Layout of Auto-line II

Coiler-aw material feeder-levelling and grooving equipment

Notch and punch square-cut metal for TDF

Cut metal for Duct

Line II can not only be used for ducting production but also for TDF (transverse duct snap flange system).

If the duct manufacture system combines a T-12, Pittsburgh lock machine, folder and shaped clip, high quality ducts can be easily produced.

NOTE:

A: It can cut set sized metal, also can be used with a plasma cutting machine.

B: (a) Punch “C”, "S” inserted cleat notch. It can cut different types of notches such as“![]() ”,“口”,and “L ”, also can be used with “C” cleat and "S" inserted flange machines.

”,“口”,and “L ”, also can be used with “C” cleat and "S" inserted flange machines.

(b) Due to different connecting methods for notch cutting, it can be used with TDF flange machine and TDF connecting machines.

(c) Notch can be used with angle iron flange or “Z” shape flange machine.

C: TDC notch can be used with inserted flange

Basic Equipment:

A: One unit of motor-driven feeding frame (two rolls)

B: one unit of leveling and grooving equipment

C: Four sets of hydraulic notch cutting dies

D: Hydraulic cutting equipment

E: Industrial computer and special software